0

0Ball Valve Overview

The ball valve evolved from the cock. Its opening and closing part acts as a sphere, and the ball is used to rotate 90° around the axis of the valve stem to achieve opening and closing purposes. Ball valves are mainly used on pipelines to cut off, distribute and change the flow direction of media.

Ball Valve Operating Instructions

1. The ball valve is a control component in the pipeline system that can quickly cut off and connect the medium flow. In order to ensure the safety of people and property, the corresponding ball valve must be correctly selected, and the installation, use and maintenance must be standardized. Copper ball valves have internal and external threads, ferrules, and methods. Blue and hot-melt connection forms are widely used in water supply, gas, HVAC, oil circuits and other systems. The sealing test strictly follows the GB/T 8464-2008 "Iron and Copper Threaded Connection Valves". It is 100% pressure tested before leaving the factory. It is qualified and shipped from the factory with the gas turned off. It is convenient to check the sealing performance on site before use.

2. The installation of valves must be carried out by professionals with relevant qualifications. The non-axial deviation of the pipelines at both ends cannot be too large, otherwise excessive pipeline installation stress will be generated, leading to failure and damage. The accuracy and effective length of pipe threads strictly comply with ISO 228 standards. The threads are all conical pipe threads, and the internal threads are cylindrical pipe thread standards.

3. When installing and tightening, the hexagonal or octagonal part on the same side of the thread should be wrenched, and the hexagonal or octagonal part on the other end of the valve should not be wrenched to avoid deformation of the valve. Polytetrafluoroethylene raw material tape must be used or thread sealant for sealing.

4. When installing and tightening the valve, you must use a corresponding torque wrench or pipe wrench. Just screw in the effective thread length. Do not overpress the inner end surface, causing damage to the surface of the ball and leakage. To ensure the normal use of the valve, install it at the pipeline inlet as much as possible. Install the filter.

5. The ball valve handle (handwheel) is designed according to the valve usage environment and corresponding torque. Do not use an enlarged arm instead to avoid damage to the valve due to excessive operating torque. At the same time, excessive closing speed will produce a water hammer effect that instantly doubles the pressure. Frequent fluctuations in pipeline pressure or temperature will reduce its life, and corresponding preventive measures should be designed.

6. The valve stem sealing packing is polytetrafluoroethylene. In case of corrosion and leakage, the gland can be tightened to compensate for the packing. To replace the packing, the medium pressure needs to be relieved. Ball valves in refrigeration and HVAC systems must use 1.6Mpa (or above nominal pressure) specifications.

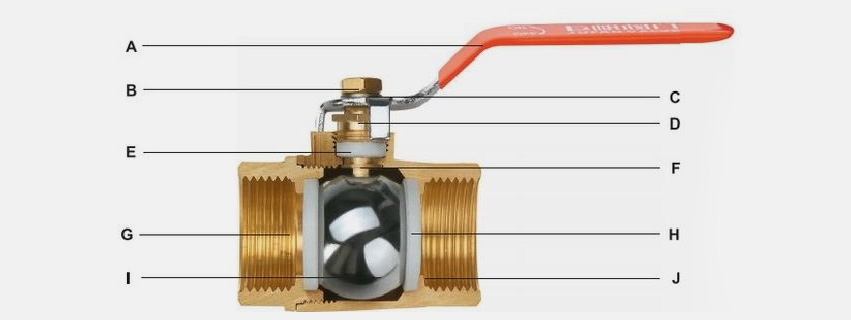

Ball Valve Structure Diagram

A.handle | B.nut | C.spring pad |

D.pressure cap | E. filler | F. Stem |

G. Bonnet | H. valve seat | I. sphere |

J. valve body |

Advantage:

1. Has the lowest flow resistance (actually zero)

2. The closing parts can withstand the high-pressure difference during closing

3. It can realize rapid opening and closing. The opening and closing time of some structures is only 0.05-0.1S to ensure that it can be used in the automation system of the experimental bench.

4. Compact structure, small size and light weight

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Tel: 0086-15651696512

WhatsApp: +86-15651696512

Email: leona@js-stone.com

Room 507, Zone C, Mingsai Technology Building, Science and Education City

Integrating the advanced manufacturing industry in China, and from the innovative thinking of the R&D department and the excellence of the production process, our products are trusted by users.

Professional, dedicated, single- minded! Is the company's long and consistent development concept.