0

0

Return water supervisor

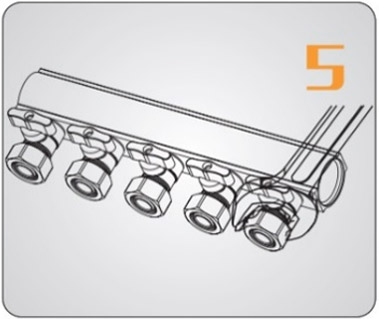

Each branch of the return water main pipe is equipped with an actuator, which can intelligently switch on and off the branch where it is located.

The plastic handle of the thermostatic valve can be replaced with a thermoelectric valve, which is connected to the indoor thermostat in the branch area. When the temperature reaches the set temperature, the thermoelectric valve automatically closes the branch.

The valve stem of the thermostatic valve is made of corrected stainless steel 304, which effectively reduces friction and prevents scaling. The valve stem has a double EPDM O-ring seal.

The piston material is EPDM, and its unique shape design optimizes the hydraulic characteristics of the thermoelectric valve and minimizes the noise of the water flow when the thermoelectric valve is opened and closed.

External branch pipe connection manifold branch connection head plus double seal

(Metal+Double-turn EPD) O-ring

Double protection of safety performance.

Branch pipe spacing 50mm.

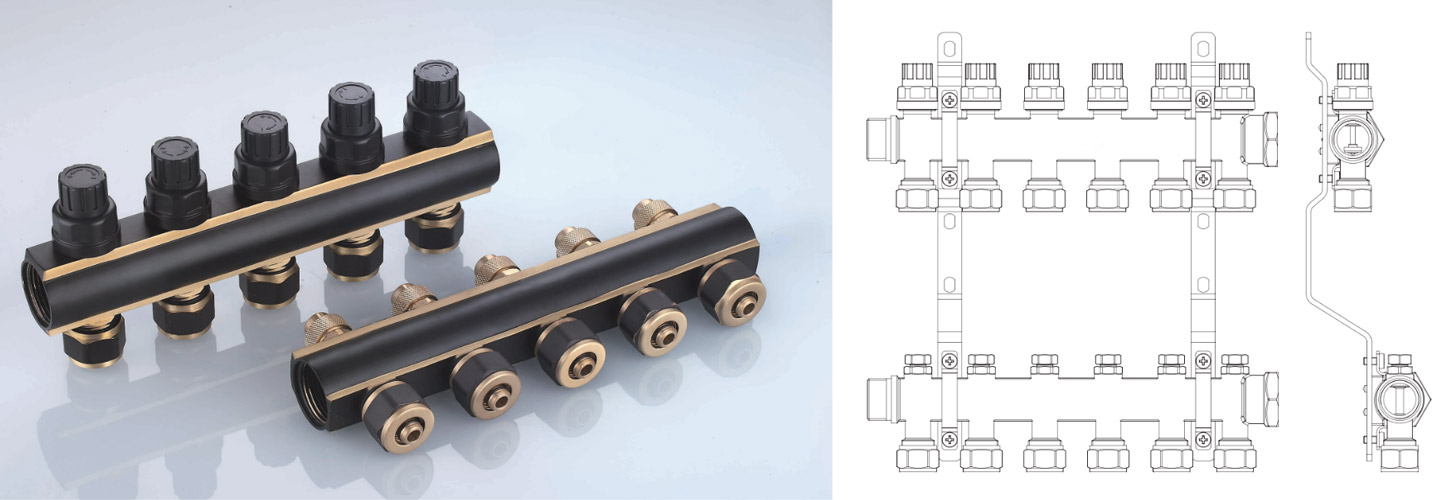

1. Raw materials used: Brass HPb58-2.

2. Intelligent structure, intelligent temperature control and room control.

3. The surface of the product is sandblasted, washed, color-sealed and glazed.

4. Structure: The water inlet is a spiral soft EPDM seal, and the return water is an intelligent temperature control valve core.

5. Nominal pressure: PN≤1.6MPa.

6. Working medium: water, non-corrosive liquid.

7. High and low temperature resistance -20° +110°.

8. Test pressure: MPa0.8~1.0.

9. Thread standard complies with ISO 228 standard.

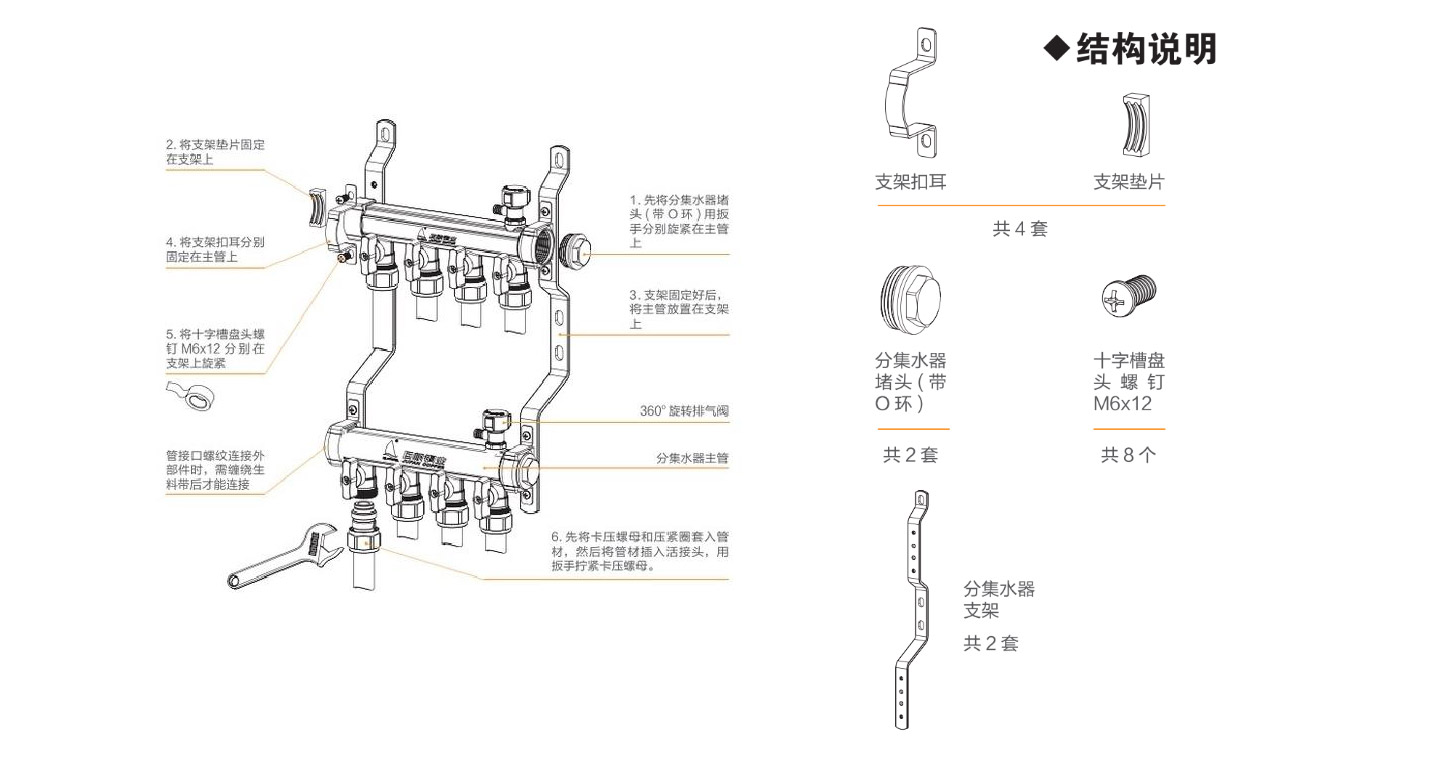

Kit information

The product is sold with: bracket, exhaust plug, hexagonal cap, spout

(Caliber 1216-1620), card sleeve, number of channels: 2 channels ~ 8 channels

Specifications product type | Forged water collector | |||||||||

Number of ways | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

Install | width(L) | 90 | 135 | 180 | 225 | 270 | 315 | 360 | 405 | 450 |

| height(H1) | 335 | ||||||||

| Center distance(L1) | 34.5 | ||||||||

Branch center distance(L2) | 45 | |||||||||

Pipe (main) body thread | 1"( internal thread) | |||||||||

Geothermal pipe interface | φ16/φ20 | |||||||||

Air tightness | 1.0Mpa±0.1Mpa, Keep it for 30s, there will be no penetration into the main body and joints. | |||||||||

◆ Product description

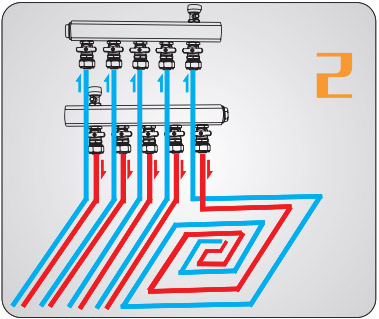

In a high-temperature heating floor heating water system, when the water temperature of the central heating or wall-mounted boiler heat source is above 60°C, the "mixed water cooling" method should be used to reduce the temperature of the floor heating circulating water so that the floor heating circulating water can work at a constant temperature. Below 60℃. Ensure that the water heating system is always in safe, energy-saving and comfortable working condition.

Safety guarantee: If the floor heating water temperature is higher than 60°C, it will affect the service life of the pipes and wooden floors (generally the service life of floor heating pipes is 50 years).

Save energy and money: High-temperature floor heating circulating water will overheat the temperature, causing a waste of heat energy. The energy-saving effect of the floor heating system is particularly significant for household metering (heat meter charging or wall-mounted boiler independent heating).

Healthy and comfortable: Floor heating is in line with the traditional Chinese medicine theory of "warming the feet and cooling the top". If the floor temperature is higher than 32°C for a long time, it will not be suitable for the health requirements of the human body.

◆ Working principle

When the primary water temperature exceeds the set temperature, the electric valve closes half of the incoming water flow; the water pump starts the cycle; the system return water enters the primary side and repeats the cycle to achieve the cooling function.

Manifold system installation instructions

Installation Steps

Personnel with relevant qualifications

Copper water collectors must be installed by professionals with relevant qualifications and debugged according to standards. It can be put into use only after passing the pressure test.

Before installation, check the laying of pipelines based on the size of the inst

Before installation, please check whether each pipeline is laid as required and whether any There is sufficient installation space and length to avoid any damage caused by forced connection. Deviation or offset of coaxiality causes assembly stress in the pipe, resulting in Cause leakage or loss of water collector. Winter installation process in cold areas , after the pressure test, the water in the system should be drained in time to prevent freezing. causing pipeline damage.

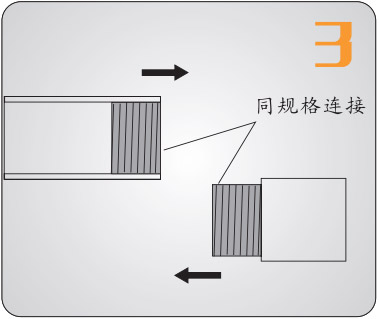

Products of the same specifications are connected to the water sub-collector

When connecting to copper manifolds, avoid connecting to products with different specifications or with excessive tolerances. When assembling plugs, valves, etc., additional sealing auxiliary items (such as raw material tapes, mahjong) should be used in an appropriate amount to avoid excessive winding and damage to the copper branch water collector main pipe.

Appropriate amount of raw material tape or hemp to assemble plugs and valves.

When connecting the sleeve type water collector joint to the pipe, avoid rotating the insertion. When tightening the pipe cap, the force must be uniform and not too fast or too hard to avoid excessive torque and damage to the valve body.

Use even force when tightening the nuts. Avoid excessive torque and damage to the valve body.

Debris in the pipeline will increase the resistance of the waterway and affect the sealing of valves and pipe fittings. It is recommended that a filter regulating valve should be installed at the inlet of the pipeline.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Tel: 0086-15651696512

WhatsApp: +86-15651696512

Email: leona@js-stone.com

Room 507, Zone C, Mingsai Technology Building, Science and Education City

Integrating the advanced manufacturing industry in China, and from the innovative thinking of the R&D department and the excellence of the production process, our products are trusted by users.

Professional, dedicated, single- minded! Is the company's long and consistent development concept.